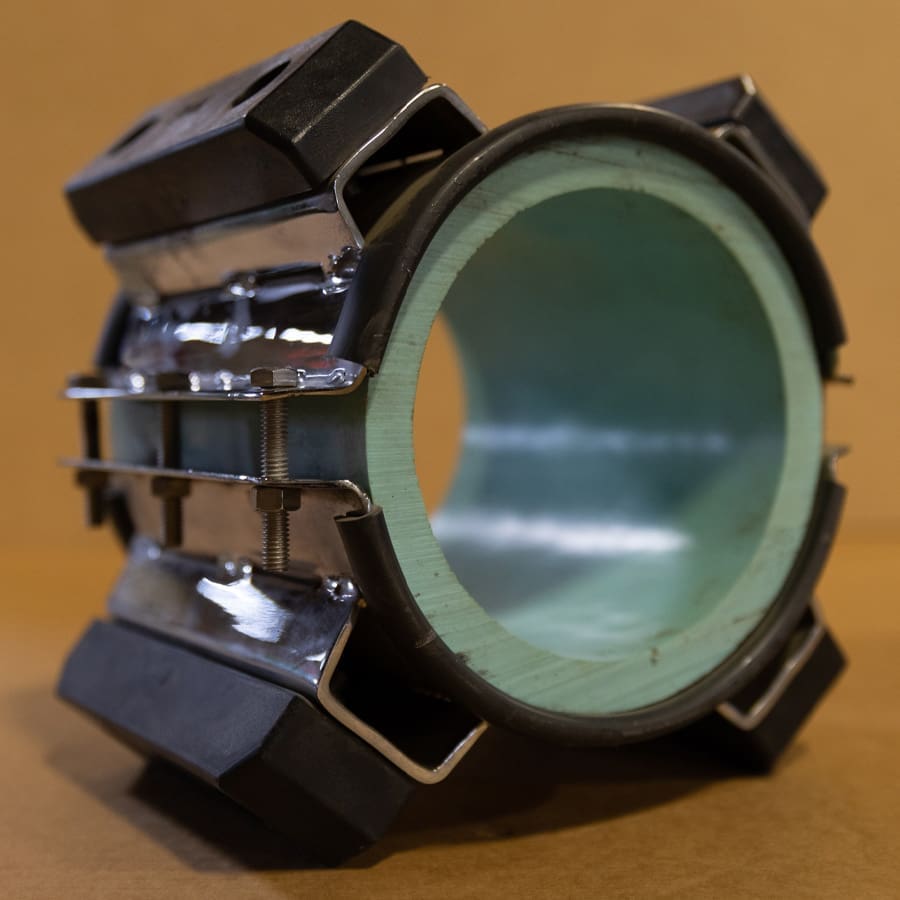

The 8” wide or 12” wide stainless steel casing spacer shall be a two piece shell made from 14 gauge T-304 stainless steel. Each shell section shall have a flange formed with ribs for strength and with a minimum of three 5/16-inch stainless steel bolts for eight inch wide and four for twelve inch wide spacers.

Each shell shall be lined with a ribbed PVC extrusion with a retaining ridge that overlaps the shell to prevent slippage. Runner surface shall be UHMW polymer or Glass Reinforced Polymer for abrasion resistance and a low coefficient of friction. The runners and risers shall be attached at appropriate positions to properly support the carrier within the casing and to ease installation.